Do you have innovative ideas, dreams or designs that are seemingly impossible? We are eager to solve your architectural challenges! Contact us so we can be of assistance.

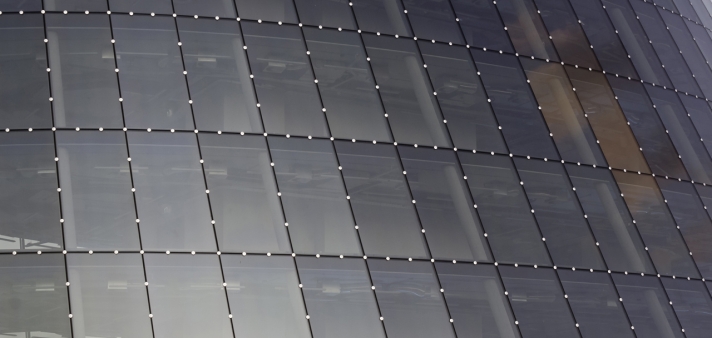

Structural glazing

The architectonic aim of Octatube’s utilization of glass, is to deliver surfaces with maximal transparency, preferably by maximizing the self supporting capabilities of glass, creating slender and elegant structures.

It is the absence of frames between the glass panels that typifies Octatube’s point-fixed glazing work. The glass may be self-supporting, or slender steel structures may be used to allow a gap to be spanned. Point connections between adjacent glass panels and to the underlying steel structure provide the glazed surface with the necessary stiffness and strength. The glass used by Octatube in these applications is generally a fully pre-stressed material, which is able to absorb up to five times the stress that can be handled by ordinary float glass. Our structural glazing techniques are primarily found in roofs and facades, but other applications are possible, including internal walls, floors, balustrades and elevators.

The term ‘structural glazing’ or ‘curtain wall’ has become quite familiar in the construction sector, but it is most commonly applied to a fully or partially framed system, in which the glass is attached to the frame with adhesives. Our system is quite different, and to avoid confusion we often refer to it as frameless glazing, point-fixed glazing or the Quattro system.

The composition of the glass panels used in frameless applications depends on project-specific requirements. Important choices need to be made between single and insulated glazing, heat-strengthened or fully tempered glazing, and laminated or single pane glazing. There are also variations in the transparency and heat transmission properties of the glass sheets used to make up the panels. Then there are choices between clear glass, tinted glass, (toughened) reflective coatings on the external or internal face, toughened or un-toughened coatings and hard or soft low emission coatings (low E) on the internal faces of cavity constructions, and graphic printing.