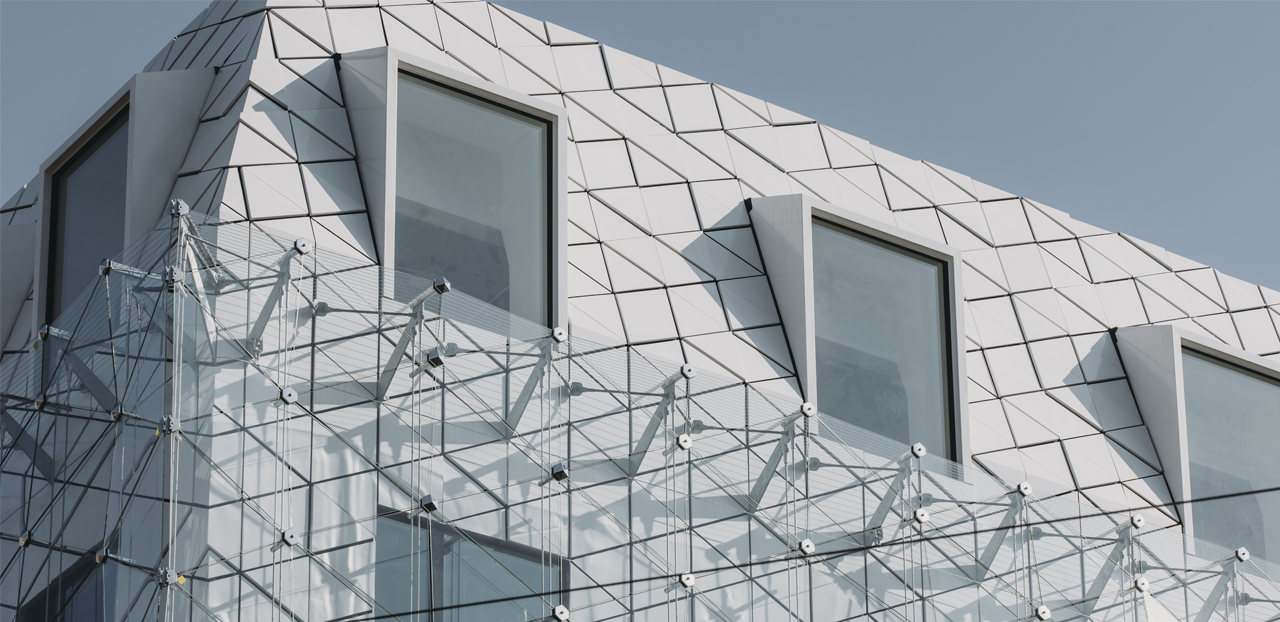

The Diamond (Heineken Hoek)

A new iconic building has appeared in the heart of Amsterdam. The transformation of the well-known Heineken Hoek on Leidseplein is finished. The old building has been demolished and a new building of six floors and a basement is build. There is space for restaurants and a four star hotel. Octatube realised the spectacular transparent hanging curtain wall and canopy that gives this new building its unique and striking look.

Diamond

The new building - designed by MVSA - has a double facade. The inner facade acts as a thermal shell and consists of triangular panels of white sheet material with different depths. This creates relief. The outer facade has no architectural function and is purely an aesthetic addition. The facade is composed of glass triangles that we placed at different angles and rotations. This gives the facade a diamond-like appearance as a reference to the famous diamond Koh-I-Nor which was cut in Amsterdam.

Cable net construction

We have suspended the facade from cables that we pre-tensioned between steel outriggers (swords) at the top and so-called nesting boxes (steel consoles in the concrete structure) at the bottom. These nesting boxes are designed in such a way that rough concrete tolerances can be translated into the very small tolerances that are necessary for the detailing of the glass facade. We poured the nesting boxes into the concrete. and measured the nesting boxes very precisely so we could drill the holes in the sealing plate at the top of the nesting boxes exactly in the right place. This is where the cables run through. The nesting boxes remain accessible for maintenance of the cable construction.

Tension rods keep the cables stable. These tension rods are as thin as possible and we only stretch them in one direction. This creates extra complexity because we now can't put pressure on the tension rods. The rods lead back to the walking grids in the space between the inner and outer facade.

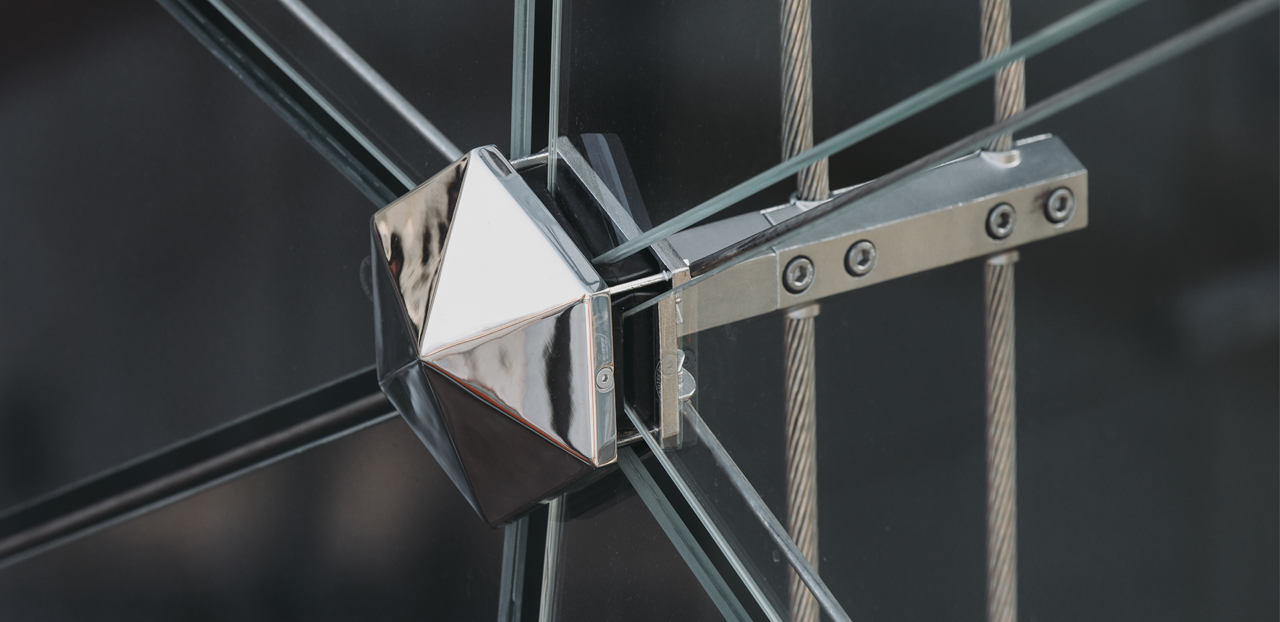

Custom made nodes

For this facade, we had specially developed elements made of plastic (pom) injection molded. We placed these elements in custom made stainless steel nodes. These nodes hold the more than 800 triangular laminated glass panels in a random distribution. The glass panels sometimes differ in size by only a few millimetres. We attached the nodes to the cables with stainless steel clamps.

Canopies and LED lighting

The glass facade continues in transparent canopies. Stainless steel swords support these glass canopies. Under these canopies are the terraces and entrances. Energy-efficient LED lighting on the inside of the façade subtly illuminates the diamond-like glass exterior in the evening.