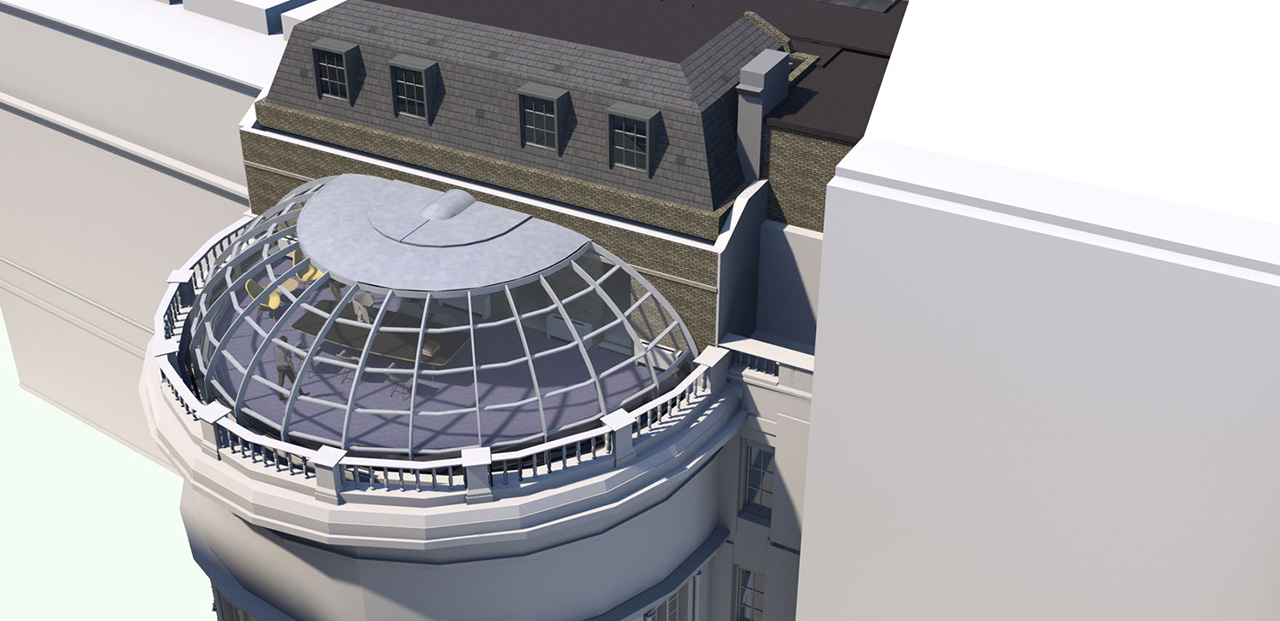

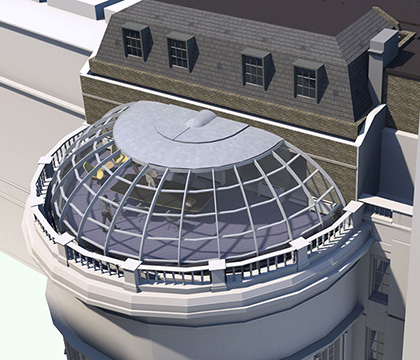

RUSI Whitehall dome

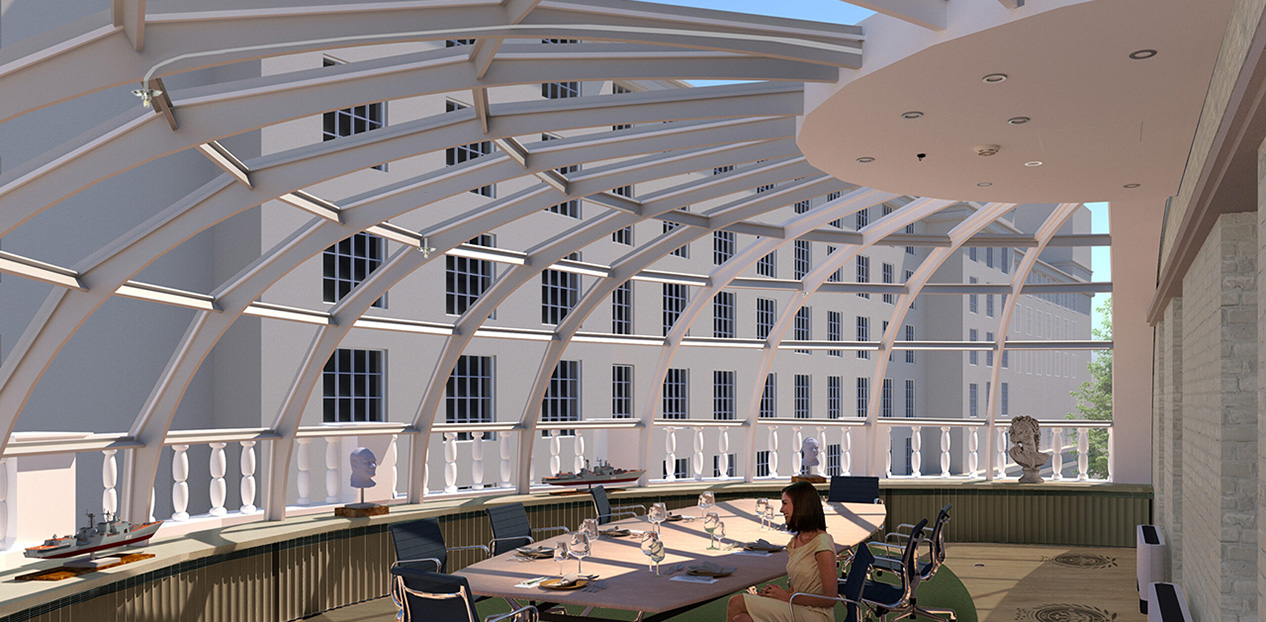

A half-dome on the roof of the iconic Royal United Services Institute (RUSI) building in the heart of London provides a stunning meeting space with spectacular views over Whitehall Gardens and the Ministry of Defense. A striking feature of this glass dome is that the glass panels can be individually adjusted from almost entirely transparent to only 10% translucent.

(Images: courtesy of Campbell Architects)

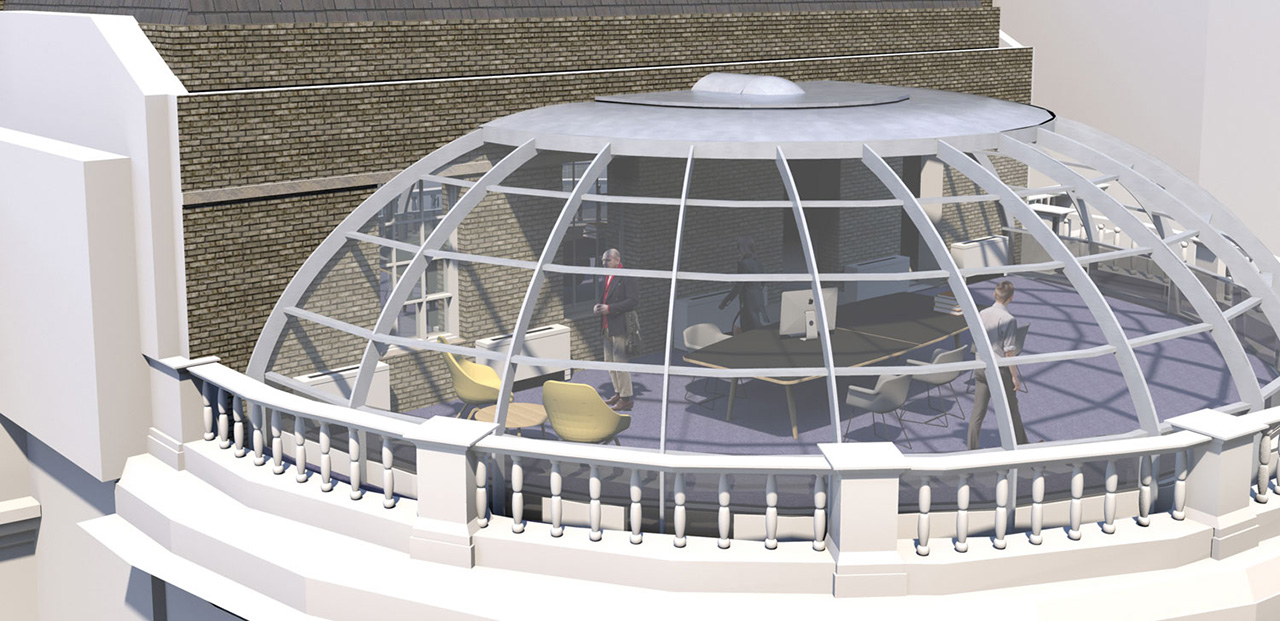

As part of a larger renovation project, RUSI's building is being expanded to include an additional meeting space by installing a glass dome on the original roof terrace - designed by Campbell Architects. The relatively flat half-dome has a diameter of 12.5 meters and a height of 4 meters. It consists of a bead-blasted stainless steel structure topped with special switchable glass panels. The dome has a zinc-finished crown as the capstone. Some glass panels function as windows that can be opened and, together with louvres in the lower ring of the dome, provide natural ventilation.

Stainless steel construction

The stainless steel construction consists of 15 custom-made curved beams that we connected with horizontal transoms. It is bead-blasted and remains in view. Therefore, we paid a lot of attention to making the connecting joints invisible. We hid all welds and bolted connections in the space under the rubbers that connect the glass and stainless steel. To absorb transverse force and torsion in the cross beams, we hid an 8mm tension bushing pin in the centre of the bodies. You can detect these pins in the minimal tolerances of the project only with a keen eye. To stabilise the construction, we added three wind braces in the bottom ring, neatly hidden under the window sill, along with the ventilation louvres.

Playing with transparency

The transparency of each glass panel is individually adjustable, from almost completely transparent to almost dark. No additional sun shading is therefore required. This system is completely integrated in the laminated glass, which therefore has a thicker composition of 6cm. The wiring runs in the joints between the glass panels and under the weatherproof sealant seams. We fixed the glass with a standard toggle system, along with standard rubbers that provide the secondary waterway.

Crown of the work

The crown of the dome is multi-functional. Under the zinc trim, we installed a roof hatch that provides access to the dome's exterior. Thanks to leash facilities on the roof, abseilers can perform future cleaning and maintenance work on the outside of the dome. In addition, we incorporated five attachment points in the crown between the dome and the existing building. We deliberately chose these five points to use the monumental building to transfer forces cleverly. Here and there, we added some auxiliary steel to the insulation.

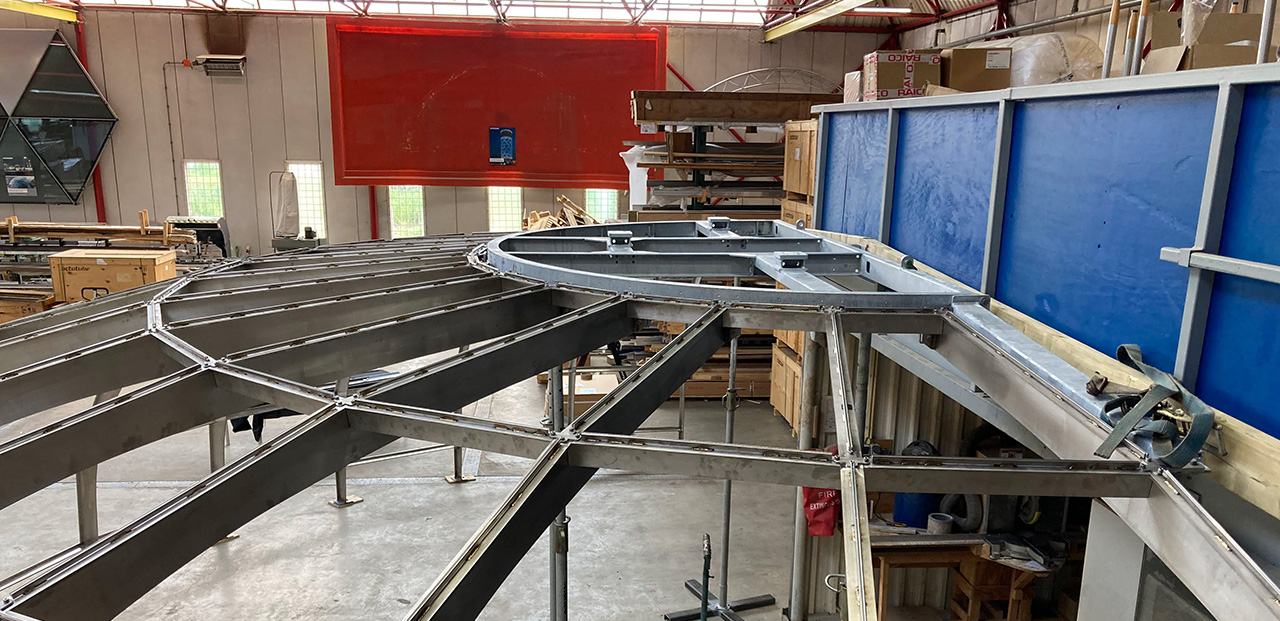

Mock-up

Octatube made a test assembly of the steel structure in our factory hall in Delft. This gave us the opportunity to test assembly sequences, assess production and see if we could achieve the desired tolerances, allowing us to ensure that construction in London takes place without major surprises. In addition, it allowed our client to come and see the finished product in advance.