Blackrock Shopping Centre

Blackrock is a suburb of Ireland’s capital Dublin. Just off Blackrock’s main street you’ll find Blackrock Shopping Centre, a shopping center originally built in 1984 and refurbished and redeveloped over the course of 2019 and 2020. Octatube engineered and built the glass and steel gridshell canopy designed by ALTU Architects.

The refurbishment entails an upgrade of the common areas as well as an extension in square meters. One of the most striking interventions is done in the existing courtyard of the shopping center. The space is now covered by a steel and glass gridshell canopy.

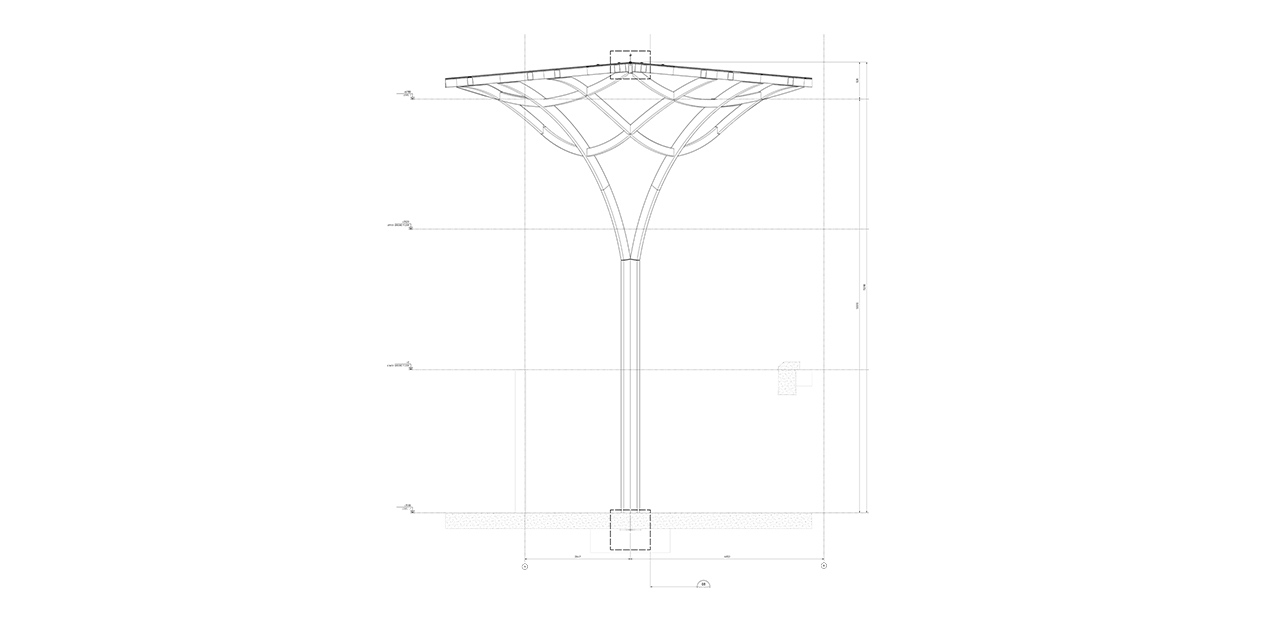

Underneath the canopy three fluent tree-shaped columns branch out under the grid. When seen from above, these steel columns have a diameter of 9 meters. The roof surface is about 1100 m2 and the steel canopy is lifted up from the roof, allowing natural ventilation. It is covered with more than 500 glass panels bringing daylight into the courtyard.

The roof surface of the canopy is flat and the structure is big with few connection points: the three columns and the edge beam. It was a structural challenge to overcome the large spans between the supports, especially given the extra weight that would be added by the glass.

Our structural engineers aligned the architectural goal with the structural goal: keeping aesthetic detailing in mind, while at the same time not to giving in on structural strength. We have aimed to make the transition from column to canopy as smooth as possible, minimizing connections. It should feel as one fluent whole, in line with the desire of ALTU Architects.

“Octatube's ingenuity has appropriately captured the original design intent effortlessly. The structures elegant fluidity will become a focal point for this centres’ transition from old to new”. Oliver Nolan, architect at ALTU Architects

Above you see the forked branches during production in our factory in Delft. They were placed upside down so our welders could easily access every part and angle. Due to their large diameter of 9 meters they couldn’t be transported in one piece. Therefore the branches were separated in different pieces, before being transported to the construction site to be bolted together. To achieve a clean and smooth finish of the steel elements our welders pursued a high-quality finish of the welding work.

In partnership with ALTU Architects, Collen Construction and Murphy Façade Studio.