Floriade Pavilion

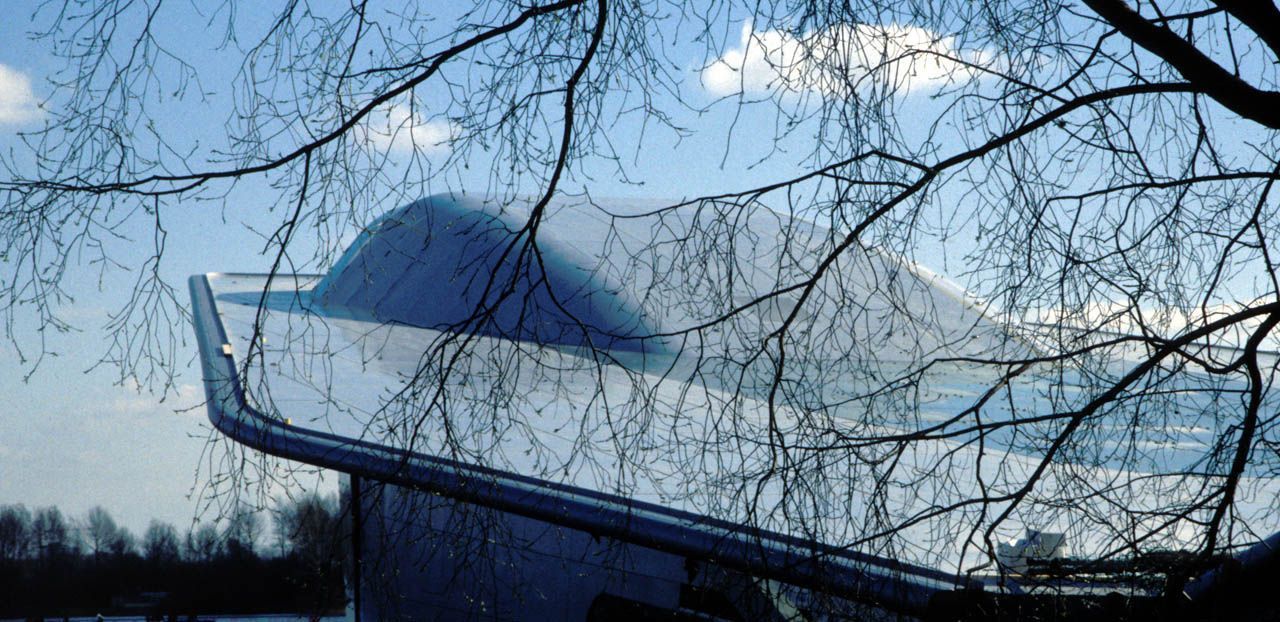

The design Asymptote Architecture for the Floriade pavilion is located on the shore of a lake. The realized pavilion exists of an artificial peninsula in the Haarlemmermeer on which a building with two sloped roofs is situated. The big roof that covers the building volume houses the entrance, exposition space and servicing spaces. The smaller roof is a freestanding canopy adjacent to a dike. A continuous stream of water flows from the top of both sloped roofs, filling the glass pond and finally flowing into two gutters on both sides of the entrance. The water streams visibly and tangibly on the inner side of two glass walls to the level of the lake.

Asymptote refers to this building as the ‘Hydra Pier’. Within this project Octatube has developed 3 innovations in building technology. After the engineering Octatube also manufactured and installed the aluminium roof, the glass pond and the structural glazing in the facades.

The first innovation was developing the 3D corners of the aluminium panel roof. This was done under supervision of ir. Karel Vollers. An extensive process of computer modeling, testing and the development of (adjustable) moulds was necessary in order to achieve the desired accuracy of the shape. The process of producing the explosion panels with a small TNT ring was very experimental.

The second innovation in the Floriade pavilion is the hanging glass pond that is developed to take on the weight of a depth of 1.41 m water, which is 12 times as much as the average roof or wall load. This has never been done before.

The shape of the pond was ideally designed by Octatube as a composition of fluent 3D shaped glass panels. But, the danger of fractures is always present. In the case of the Municipal Floriade Pavilion, whereas a possible replacement could take up to several months, this would’ve been a disaster. Therefore a simpler solution, namely a polygonal variety, was chosen and realized.

The fluent transformed and chemically pre-stressed laminated structural frameless glass was a bridge too far for the client after all, but a persistent challenge for experimental product developers.

The completely pre-stressed glass is without holes, but kept frameless by elliptical dishes connected by seams. Three problems needed to be overcome in this solution: the deflection under the continuous weight of the water, the waterproofing of the pond and the corrosion of the water on the laminate in the glass panels. High bending stresses occur in the glass.

The third innovation is executed in the south facade. This façade exists of three glass surfaces of approximately 6x6 square meters, each divided in 3x3 panels of maximally 2x2 square meters. Both surfaces on the side are bent with a diameter of 2.5 meters. The three stacked corner panels were manufactured as 12 millimeters thick monolithic thermal pre-stressed glass panels. In addition 2x6 non-orthogonal panels, each 2x2 square meters in laminated completely pre-stressed glass were cold bent on the construction site.

The Hydra Pier is the only pavilion that had got a permanent character and was not disassembled or demolished after the Floriade event in 2002.