Membranes

Since the 80’s Octatube has been realizing membrane structures for a wide variety of projects.

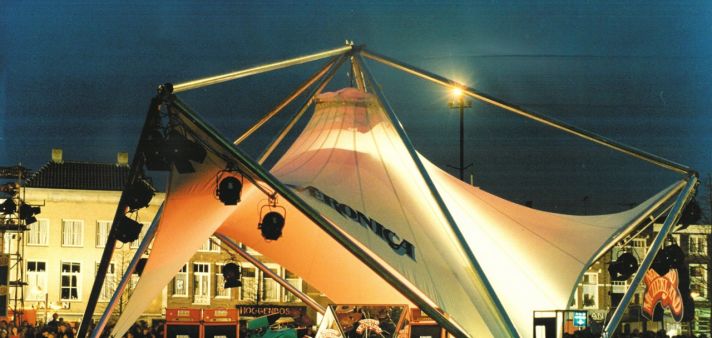

Tensioned membrane structures or “tents” in their architectonic and sculptural manifestations have been familiar since the 1960s work of Frei Otto of Stuttgart. The main use of the tent in the Netherlands has been as an “urban umbrella”, where the tent functions as a canopy, a shelter from the rain/sun or a freestanding roof, for example over a shopping centre. The most common form is a roof surface combining convex and concave curves. This arrangement allows the fibers in the reinforcement woven into the cloth to support one another as the wind loading fluctuates. Tensioned cables running with a concave or convex curve through the roof material, stiff compression members in steel tube or laminated timber, or steel masts to lift the membrane, reinforced if necessary with guy ropes, serve to maintain the so-called “anticlastic” form of the membrane with its opposing curves. The successful design of membrane structure calls for close collaboration between the project architect and construction contractor on the one hand and the product designer and the product manufacturer on the other, with a joint approach to the design right from the outset. Tensioned membranes are always special products. The direct influence of the dimensions of supporting and other structures in the vicinity mean that one design rarely duplicates another. In the Netherlands the smaller membranes generally use polyester-reinforced PVC fabric with a lifespan of fifteen to twenty years.

In addition, there are applications with the Teflon-based PTFE and ETFE. Almost transparent materials which often are applied with air pressured cushions as a building skin. Compared to glass they are less transparent and more prone to punctures, but they are recyclable and especially many times lighter.

Membranes

Since the 80’s Octatube has been realizing membrane structures for a wide variety of projects.

Tensioned membrane structures or “tents” in their architectonic and sculptural manifestations have been familiar since the 1960s work of Frei Otto of Stuttgart. The main use of the tent in the Netherlands has been as an “urban umbrella”, where the tent functions as a canopy, a shelter from the rain/sun or a freestanding roof, for example over a shopping centre. The most common form is a roof surface combining convex and concave curves. This arrangement allows the fibers in the reinforcement woven into the cloth to support one another as the wind loading fluctuates. Tensioned cables running with a concave or convex curve through the roof material, stiff compression members in steel tube or laminated timber, or steel masts to lift the membrane, reinforced if necessary with guy ropes, serve to maintain the so-called “anticlastic” form of the membrane with its opposing curves. The successful design of membrane structure calls for close collaboration between the project architect and construction contractor on the one hand and the product designer and the product manufacturer on the other, with a joint approach to the design right from the outset. Tensioned membranes are always special products. The direct influence of the dimensions of supporting and other structures in the vicinity mean that one design rarely duplicates another. In the Netherlands the smaller membranes generally use polyester-reinforced PVC fabric with a lifespan of fifteen to twenty years.

In addition, there are applications with the Teflon-based PTFE and ETFE. Almost transparent materials which often are applied with air pressured cushions as a building skin. Compared to glass they are less transparent and more prone to punctures, but they are recyclable and especially many times lighter.